The Company started at 2015 in Sipcot, Hosur, Tamilnadu, has wide experience in Design and Manufacturing of products ranging from Dies, Molds, Jigs & Fixtures, to CNC Machines for customized applications.

The Startup team comprises of graduates from IITs, IIMs and other leading Indian Institutes. The Team members brings in experience from World leading companies like GE Aviation, Boeing, Taneja Aerospace, Renault Nissan and NTTF etc…

NOVATEK is a customer centric, focuses on complete product solutions. Novatek provides one stop solutions in Design, Drafting, Analysis and Manufacturing for Automotive and Aerospace Industries requirements.

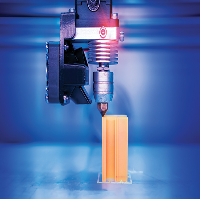

NOVATEK specializes in Design and Manufacturing of Mechanical Systems, Industrial Automation, Industrial IoT and 3D Printing services. The Company is located in Hosur, Tamilnadu and has wide experience in manufacturing of Press Tools, Die casting Dies, Injection Moulds, Jigs & Fixtures and Gauges in the field of Aerospace and Automotive.

Novatek offers an highly integrated smart cyber physical space, it opens the door to create whole new business and market opportunities for manufacturing.The IoT intelligent systems enable rapid manufacturing of our new products, dynamic response to product demands, and real-time optimization of manufacturing production and supply chain networks, by networking machinery, sensors and control systems together.

Working with your design and development teams, we can offer our Test bench support throughout the product development process.we can help you ensure that you launch the best version possible of your product. Post launch we can provide accurate scale or cutaway models for Marketing and exhibitions too. Novatek leverages the extensive deployment experience, Rapid technologies delivers both custom developed and out of box for enterprise service management solutions.

Novatek offers an highly integrated smart cyber physical space, it opens the door to create whole new business and market opportunities for manufacturing.The IoT intelligent systems enable rapid manufacturing of our new products, dynamic response to product demands, and real-time optimization of manufacturing production and supply chain networks, by networking machinery, sensors and control systems together.

Working with your design and development teams, we can offer support throughout the product development process.we can help you ensure that you launch the best version possible of your product. Post launch we can provide accurate scale or cutaway models for Marketing and exhibitions too. Novatek leverages the extensive deployment experience, Rapid technologies delivers both custom developed and out of box for enterprise service management solutions.

Using Industrial Robots to Automate applications throughout your production line to save time and money. Robots can also handle the most tedious and dangerous manufacturing applications to keep your workers safe, healthy and motivated. Novatek offers comprehensive and cost effective solution to complex industrial automation requirements. Our team comprises experienced engineers who continuously enhances the advancement in automation systems and technology to optimize our customers’ complex industrial process.

As many industries move towards Additive manufacturing for rapid prototyping, Novatek offers solutions for all our customer requirements in all Test rigs at affordable prices. With our advanced technology Automatic, Semi-Automatic and experienced professionals, Novatek offers optimized product design and prototypes that enables customer develop their new products at faster and cheaper rates.

We offer to our clients a range of intelligent, flexible, powerful, expandable and effective programmable logic relays with expandable I/Os, Analog I/Os, High Speed Counters,Communication Options. We also provide solutions for Pick & Place systems along with Advanced Machine Vision,Barcode reader sysytems. Supervisory control and data acquisition (SCADA) is a control system architecture that uses computers, networked data communications and graphical user interfaces for high-level process supervisory management. Our Experts provide secured & Customized SCADA system.

Solar powered electric auto, drive the vehicle for whole day without charging. Dybamic design, with the strong body and chasis, Top speed upto 30kmph with the powerful battery of 48v 30ah Li-ion battery and assembled within a prototype project. Lithium Ion batteries are the present optimal choice for mobile power from the technical side. The general high cost of such an mobile off-grid energy supply leads to employing cells in re-use. An application-adapted battery management system is realized for that purpose. In order to accomplish start-up of the induction machine some additional circuits are included.

The idea of ‘Drive-by-wire’, the control of a car’s vital functions like steering and breaks by electrical rather than mechanical links, it tantalizing to some and terrifying to other. By-wire systems are a means for quick communication between the driver and the components that control the vehicle. Every action that a vehicle can make (i.e. turning, accelerating, braking) is controlled via an actuator or motor. Each motor is controlled by an electronic signal via some form of human-vehicle interface (i.e. a steering wheel, a brake pedal or throttle pedal). One of the biggest advantages is that they react more quickly and thus are more responsive than the mechanical equivalent. Conventional vehicles use mechanical linkages to actuate motion, which requires energy transfer from one link to another.

Small lawn-mowers powered by low-energy lithium batteries are on the market already. However, battery powers only the grass cutting blades while propulsion is to be done manually. Standard self-propelling lawn-mowers use noisy combustion engines or 230 V AC supplied single-phase induction machines. A self-propelled battery powered lawn-mower is developed and assembled within a prototype project. Lithium Ion batteries are the present optimal choice for mobile power from the technical side. The general high cost of such an mobile off-grid energy supply leads to employing cells in re-use. An application-adapted battery management system is realized for that purpose. As the 230 V AC drive is the original grid-powered one, we insert a commercial 12 V DC => 230 V AC inverter. In order to accomplish start-up of the induction machine some additional circuits are included.

Vehicle-to-grid (V2G) describes a system in which plug-in electric vehicles, such as battery electric vehicles (BEV), plug-in hybrids (PHEV) or hydrogen fuel cell electric vehicles (FCEV), communicate with the power grid to sell demand response services by either returning electricity to the grid or by throttling their charging rate.[1][2][3] V2G storage capabilities can enable EVs to store and discharge electricity generated from renewable energy sources such as solar and wind, with output that fluctuates depending on weather and time of day.

Plot No.240,Survey No-43/2,

Govinda Agraharam,Rajeshwari Layout,

Sipcot Phase-1, Hosur,

Tamilnadu-635126

Tel: +91 9597730787; +91 9686624595

Email: info@novatek.co.in; novatekengineering@gmail.com

Visit Our Blog : Novatek Blog

Whatsapp : Message Us Online